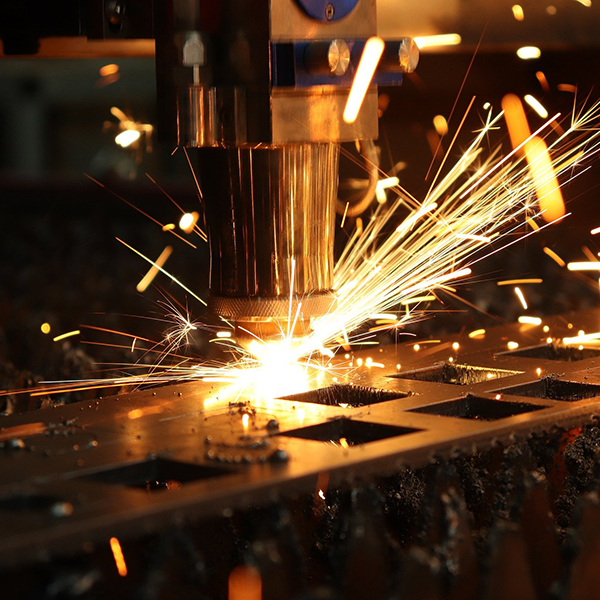

Laser cutting machines are an incredibly useful tool in a wide range of industries, from manufacturing to architecture. They are able to make precise cuts in a variety of materials, including metal, wood, and plastic, with minimal waste and high accuracy. However, like any technology, laser cutting machines also come with their own set of challenges that can impact their performance and efficiency. In this post, we’ll explore some of the most common challenges in laser cutting machines and how to address them.

- Material compatibility

One of the biggest challenges in laser cutting is material compatibility. While laser cutting can be used on a wide range of materials, some materials are more difficult to cut than others. For example, materials with a high reflectivity, such as copper or aluminum, can reflect the laser beam and cause damage to the machine. Similarly, some materials may emit hazardous fumes or particles when cut, which can pose a health risk to workers and damage the machine.

To address these challenges, it is important to carefully select the appropriate laser and cutting parameters for each material. Laser manufacturers often provide guidance on material compatibility and recommended settings for specific materials. Additionally, it is important to ensure that the laser cutting machine is properly ventilated and equipped with appropriate safety features to protect workers and the machine from hazardous fumes and particles.

- Cutting speed

Cutting speed is another challenge in laser cutting, as it can impact the quality of the cut and the overall efficiency of the machine. Cutting too slowly can result in excessive heat buildup and deformation of the material, while cutting too quickly can result in incomplete cuts and rough edges.

To optimize cutting speed, it is important to choose the appropriate laser power and pulse rate for each material and thickness. Additionally, the machine should be properly maintained to ensure that the cutting head is in good condition and the machine is running at optimal performance.

- Maintenance and upkeep

Like any piece of equipment, laser cutting machines require regular maintenance and upkeep to ensure optimal performance and prevent breakdowns. This can include cleaning the cutting head, checking the alignment of the laser beam, and replacing worn or damaged components.

To ensure that the machine is properly maintained, it is important to follow the manufacturer’s recommended maintenance schedule and perform routine checks and inspections. Additionally, it is important to train workers on proper machine operation and maintenance to minimize the risk of damage or breakdowns.

- Cost

Laser cutting machines can be a significant investment for many businesses, and cost is a common challenge in purchasing and operating these machines. The cost of the machine itself, as well as ongoing maintenance and upkeep, can be a barrier for some businesses.

To address this challenge, it is important to carefully consider the specific needs of the business and select a machine that is appropriate for those needs. Additionally, it may be possible to reduce costs by purchasing a used machine or leasing a machine rather than purchasing one outright.

In conclusion, laser cutting machines are an incredibly useful tool in many industries, but they also come with their own set of challenges. By carefully selecting the appropriate laser and cutting parameters for each material, optimizing cutting speed, performing regular maintenance and upkeep, and carefully considering cost, businesses can overcome these challenges and make the most of their laser cutting machines.