Introduction:

In the medical device manufacturing industry, precision and accuracy are crucial factors for the quality and safety of the finished products. The femto second laser cutting technology is one of the most advanced and effective techniques for cutting tubes and other profiles used in the manufacturing of medical devices. Compared to other laser cutting methods, such as nano second fiber lasers, femto second laser cutting offers several advantages that can benefit the industry.

In this post, we will explore the femto second laser cutting technology and its applications in the medical device manufacturing industry. We will also compare it with the nano second fiber laser alternative and highlight the advantages and disadvantages of each method.

Femto Second Laser Cutting Technology:

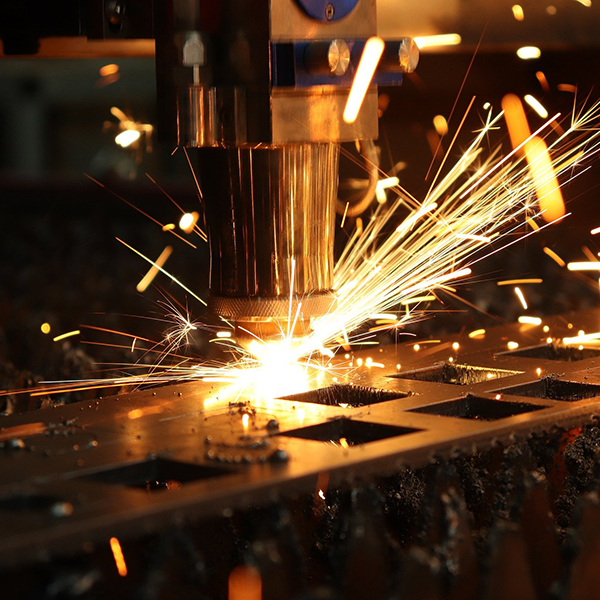

Femto second laser cutting is a high-precision laser cutting method that uses ultra-short laser pulses to cut through various materials with high accuracy and minimal damage to the surrounding area. The laser pulses used in femto second laser cutting are in the range of femto seconds (10^-15 seconds), which is much shorter than the pulses used in nano second fiber laser cutting.

The femto second laser cutting technology offers several advantages over other laser cutting methods. One of the most significant advantages is the high precision and accuracy of the cuts. The ultra-short laser pulses can cut through even the thinnest materials with a high level of accuracy, making it ideal for cutting complex shapes and intricate designs. The technology also offers a high degree of flexibility, allowing manufacturers to cut a wide range of materials, including metals, plastics, and ceramics, without damaging the material or the surrounding area.

Another advantage of femto second laser cutting is the minimal heat transfer during the cutting process. The ultra-short laser pulses generate very little heat, reducing the risk of thermal damage to the material being cut. This is particularly important in the medical device manufacturing industry, where the quality and safety of the finished product are paramount. By minimizing the heat transfer during the cutting process, femto second laser cutting can help ensure the quality and integrity of the finished product.

Femto Second Laser Cutting Applications in the Medical Device Manufacturing Industry:

The medical device manufacturing industry is one of the primary beneficiaries of femto second laser cutting technology. The high precision and accuracy of the cuts make it ideal for cutting complex shapes and designs, particularly in medical devices that require intricate designs and high-quality finishes.

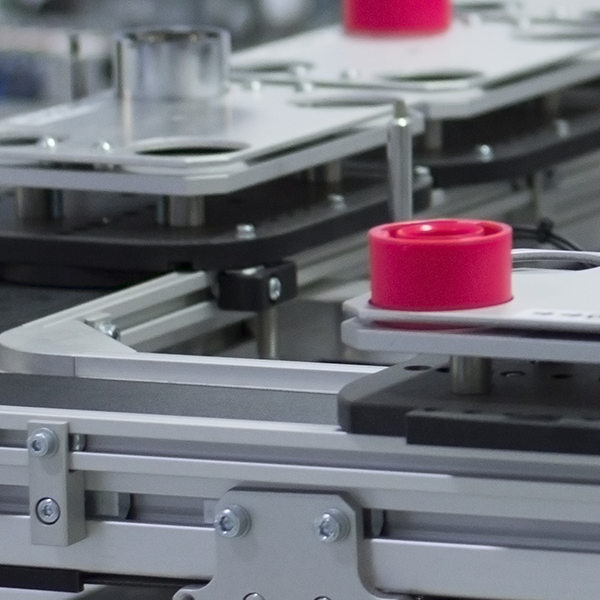

One of the most significant applications of femto second laser cutting in the medical device manufacturing industry is in the production of stents. Stents are small, tube-like devices that are inserted into blood vessels to help keep them open. The production of stents requires high-precision cuts to ensure that they fit perfectly inside the blood vessels. Femto second laser cutting technology can provide the level of precision and accuracy required to produce stents that fit perfectly and work effectively.

Femto second laser cutting is also used in the production of catheters, another essential medical device. Catheters are thin, flexible tubes that are inserted into the body to deliver fluids or medications. The production of catheters requires precision cuts to ensure that they are the right length and shape. Femto second laser cutting technology can provide the level of precision required to produce catheters that are safe and effective.

In addition to stents and catheters, femto second laser cutting is used in the production of other medical devices, including implants, surgical instruments, and diagnostic tools. The high precision and accuracy of the cuts can help ensure the safety and efficacy of these devices.

Comparison with Nano Second Fiber Laser Cutting:

While femto second laser cutting offers several advantages over other laser cutting methods, such as traditional fiber laser cutting, it is not the only option available. Nano second fiber laser cutting is another method that is commonly used in the medical device manufacturing industry.

Nano second fiber laser cutting uses longer laser pulses than femto second laser cutting, typically in the range of nanoseconds (10^-9 seconds), to cut through materials. While this method may not offer the same level of precision and accuracy as femto second laser cutting, it is still a highly effective method for cutting tubes and other profiles.

One of the advantages of nano second fiber laser cutting is its lower cost compared to femto second laser cutting. While the initial investment in fiber laser cutting equipment may be higher, the ongoing costs of using this method are lower than femto second laser cutting. This can make it a more cost-effective option for some manufacturers, particularly those with lower production volumes.

Another advantage of nano second fiber laser cutting is its ability to cut through thicker materials. While femto second laser cutting is highly effective at cutting through thin materials, it may not be as effective on thicker materials. In contrast, nano second fiber laser cutting can cut through a wider range of materials, including thicker metals and plastics.

However, there are also several disadvantages to using nano second fiber laser cutting in the medical device manufacturing industry. One of the most significant disadvantages is the heat transfer during the cutting process. The longer laser pulses used in this method generate more heat than femto second laser cutting, increasing the risk of thermal damage to the material being cut. This can compromise the quality and integrity of the finished product, which is particularly concerning in the medical device manufacturing industry where safety is paramount.

Another disadvantage of nano second fiber laser cutting is its limited ability to cut complex shapes and designs. While it is still a highly effective method for cutting tubes and other profiles, it may not be suitable for cutting more intricate designs and shapes. This can limit the range of medical devices that can be produced using this method.

Conclusion:

Femto second laser cutting technology is an advanced and highly effective method for cutting tubes and other profiles in the medical device manufacturing industry. Its high precision and accuracy make it ideal for producing complex and intricate designs, while its minimal heat transfer helps ensure the quality and integrity of the finished product.

While nano second fiber laser cutting is also a highly effective method for cutting tubes and other profiles, it may not offer the same level of precision and accuracy as femto second laser cutting. Its lower cost and ability to cut through thicker materials make it a viable alternative for some manufacturers, but its higher heat transfer and limited ability to cut complex shapes may limit its use in the medical device manufacturing industry.

Ultimately, the choice between femto second laser cutting and nano second fiber laser cutting will depend on the specific needs and requirements of each manufacturer. However, for those looking for the highest level of precision and accuracy, femto second laser cutting is the preferred option in the medical device manufacturing industry.