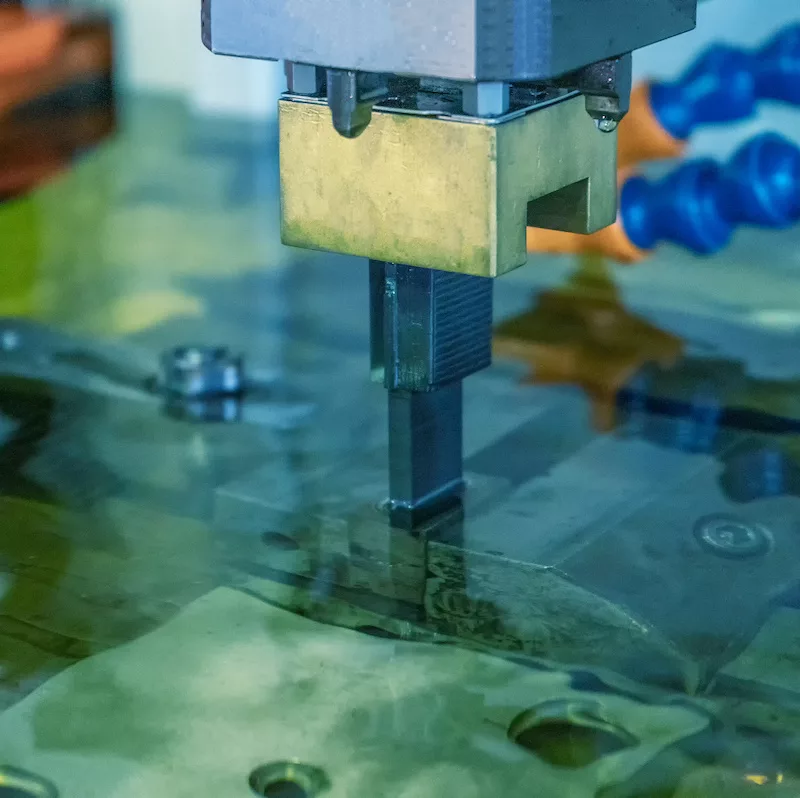

Why EDM Machines are an important cornerstone of manufacturing.

Electrical Discharge Machines (EDM) have revolutionized the manufacturing industry, particularly in the production of complex shapes and high-precision components. These machines use electrical discharges to erode material from the workpiece, resulting in a finished product that is accurate to within a few microns. In this post, we’ll explore the advantages of EDM machines over traditional milling machines and how they can benefit your manufacturing process.

- Accuracy and Precision

EDM machines are renowned for their accuracy and precision. They can create complex shapes and intricate designs that would be difficult or impossible to achieve using traditional milling machines. EDM machines are particularly useful for producing small and delicate components, such as gears and turbine blades, where precision is critical. Additionally, the accuracy of the EDM process is consistent across all materials, including hard metals and alloys, which are difficult to work with using traditional milling machines.

- No Direct Contact with Workpiece

Another significant advantage of EDM machines is that they do not require direct contact with the workpiece. Instead, an electrical discharge is used to erode the material, resulting in a finished product with no mechanical stress or distortion. This is particularly important when working with delicate materials or when producing parts with complex geometries that are difficult to machine using traditional methods. Additionally, the lack of direct contact with the workpiece means that there is no risk of tool wear, which can lead to inaccuracies and defects.

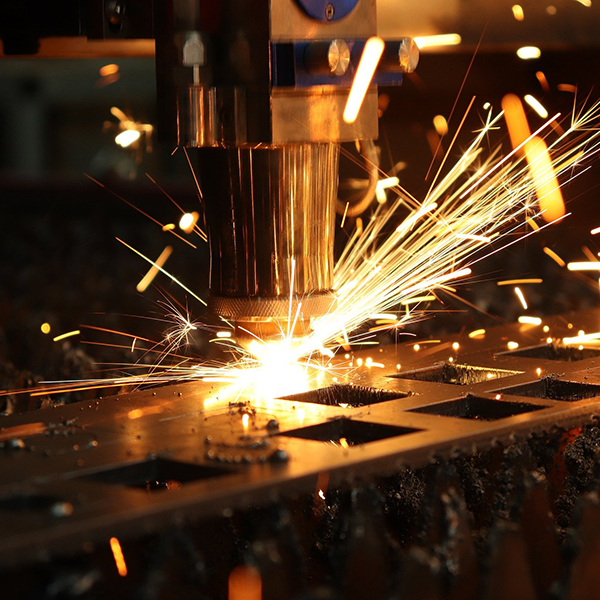

- Wide Range of Materials

EDM machines can work with a wide range of materials, including metals, alloys, and even ceramics. This versatility makes them ideal for producing components for various industries, such as aerospace, medical, and automotive. Additionally, EDM machines can work with materials that are difficult to machine using traditional milling machines, such as hardened steel and tungsten carbide.

- Cost-Effective

While EDM machines may have a higher upfront cost compared to traditional milling machines, they are more cost-effective in the long run. The lack of tool wear and the ability to work with a wide range of materials means that the cost per part is significantly lower than traditional machining methods. Additionally, the accuracy and precision of EDM machines reduce the need for secondary operations, resulting in shorter production times and reduced labor costs.

- Environmentally Friendly

Finally, EDM machines are environmentally friendly compared to traditional milling machines. The lack of direct contact with the workpiece means that there is no risk of coolant contamination, which can be harmful to the environment. Additionally, the EDM process generates no chips or waste material, resulting in minimal material waste.

In conclusion, EDM machines offer significant advantages over traditional milling machines in terms of accuracy, precision, versatility, cost-effectiveness, and environmental impact. If you’re looking for a reliable and efficient way to produce high-precision components with complex shapes, EDM machines are an excellent investment for your manufacturing process.