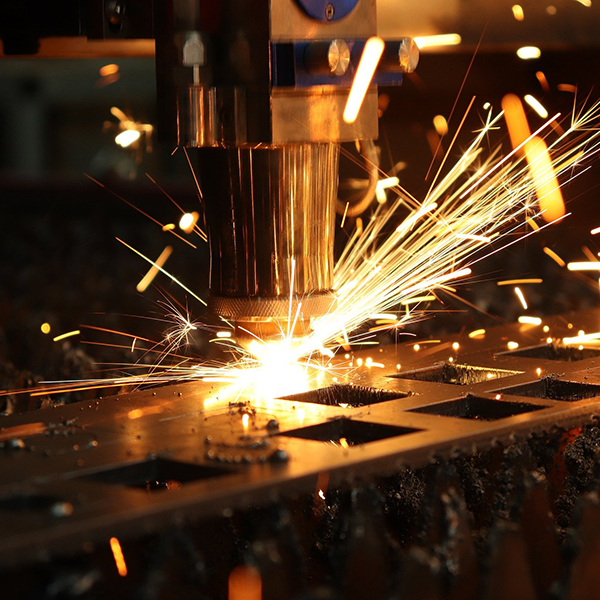

Laser cutting is a widely used technology in modern manufacturing processes. It provides a precise and efficient way to cut through a variety of materials such as metals, plastics, and wood. One of the key components in laser cutting is the use of auxiliary gases, which play an essential role in the quality and efficiency of the cutting process. In this article, we will explore the benefits of using auxiliary gases in laser cutting and compare it with other technologies such as Electro-Erosion and Water-Jet cutting.

Auxiliary Gases in Laser Cutting

The primary function of auxiliary gases in laser cutting is to help remove the molten material from the cut. The laser beam heats the material to its melting point, and the auxiliary gas (usually oxygen, nitrogen, or argon) blows the molten material away from the cut, creating a clean and precise cut. The use of auxiliary gases also helps to prevent the material from re-solidifying, which can cause burrs and rough edges.

Another benefit of using auxiliary gases is that they can improve the speed and efficiency of the cutting process. By increasing the flow rate of the gas, the material can be cut at a faster rate, allowing for more parts to be produced in a shorter amount of time. Additionally, the use of auxiliary gases can reduce the amount of heat that is transferred to the material, which can help to prevent warping and distortion of the final product.

Types of Auxiliary Gases

There are several different types of auxiliary gases that can be used in laser cutting, each with its own benefits and drawbacks. The most commonly used gases are oxygen, nitrogen, and argon.

Oxygen is often used when cutting materials such as steel, stainless steel, and aluminum. It reacts with the material to create a chemical reaction that helps to speed up the cutting process. However, the use of oxygen can also cause the material to oxidize, which can create a rougher edge on the final product.

Nitrogen is often used when cutting materials such as copper, brass, and titanium. It helps to prevent oxidation and can create a cleaner cut than oxygen. However, nitrogen is not as efficient as oxygen, so it may take longer to cut through thicker materials.

Argon is often used when cutting materials that require a high degree of precision, such as medical devices and electronic components. It creates a clean and precise cut, but it is not as efficient as oxygen or nitrogen.

Comparison with Electro-Erosion and Water-Jet Cutting

While laser cutting with auxiliary gases provides many benefits, there are other technologies that can also be used to cut materials. Two of the most popular alternatives to laser cutting are Electro-Erosion and Water-Jet cutting.

Electro-Erosion cutting, also known as EDM (Electrical Discharge Machining), uses electrical sparks to cut through the material. This method is particularly effective for cutting through hard materials such as hardened steel, carbide, and titanium. However, the process can be slow and expensive, and it may not be suitable for cutting thin materials.

Water-Jet cutting uses a high-pressure stream of water to cut through the material. It is particularly effective for cutting through materials such as glass, ceramics, and composites. However, the process can be slow and may not be suitable for cutting through thick materials.

In comparison, laser cutting with auxiliary gases offers several advantages over Electro-Erosion and Water-Jet cutting. It is faster and more efficient than Electro-Erosion cutting, and it can cut through thicker materials than Water-Jet cutting. Additionally, laser cutting with auxiliary gases offers a high degree of precision and can produce clean and precise cuts with minimal waste.

Conclusion

In conclusion, the use of auxiliary gases in laser cutting plays an essential role in producing high-quality and efficient cuts. The use of oxygen, nitrogen