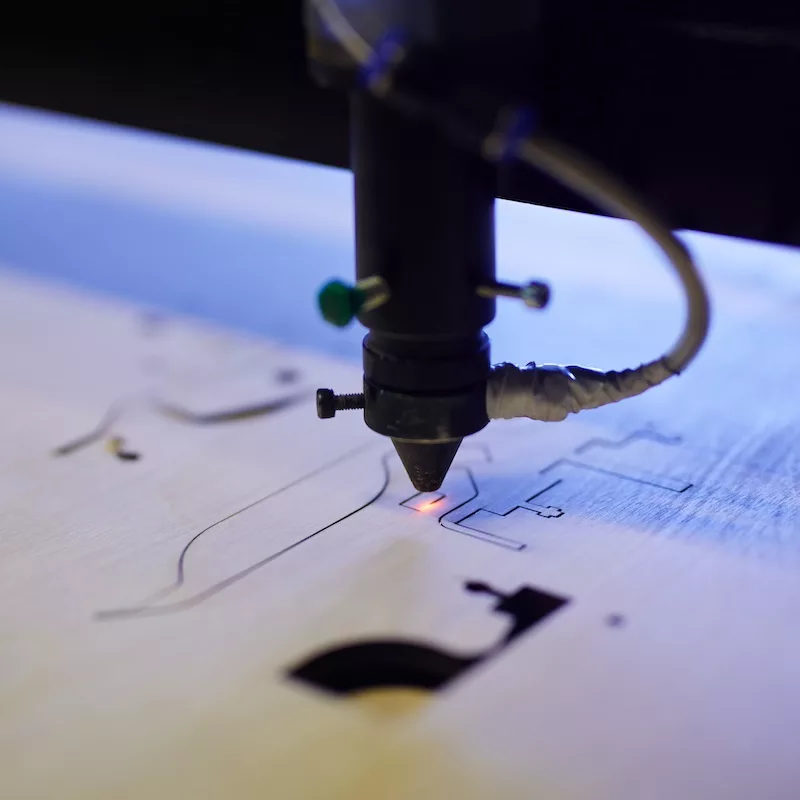

When it comes to maximizing the efficiency and precision of your CO2 laser system, selecting the right focus lens is crucial. The focus lens plays a pivotal role in determining the quality of laser cutting and engraving. In this blog post, we will delve into the factors that influence the choice of a focus lens and guide you through the process of finding the ideal lens for your CO2 laser application.

Understanding CO2 Laser Systems:

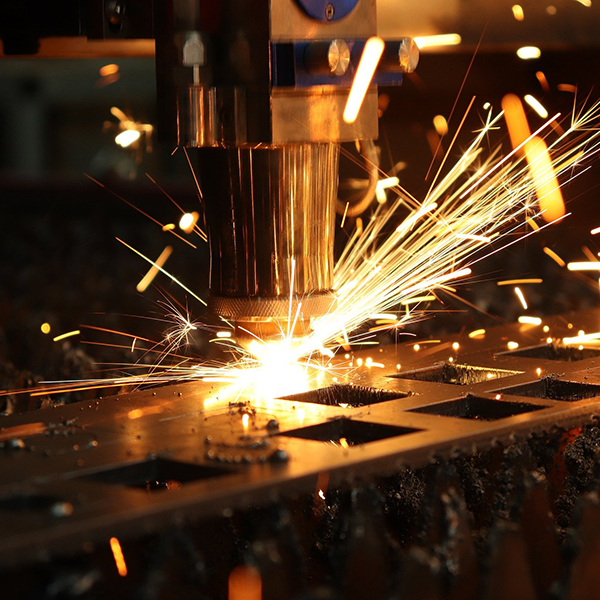

CO2 lasers operate in the infrared spectrum, typically at wavelengths around 10.6 micrometers. These lasers are widely used for cutting, engraving, and marking various materials, including wood, acrylic, glass, and metals. The focus lens in a CO2 laser system is responsible for converging the laser beam to a tight focal point, ensuring optimal material processing.

Factors to Consider:

- Focal Length:

- The focal length of a lens is the distance from the lens to the focal point. It directly affects the spot size and depth of field. Shorter focal lengths result in smaller spot sizes but also reduce the depth of field. Longer focal lengths provide a larger depth of field but may have a larger spot size. Choose a focal length based on the thickness and type of material you’ll be working with.

- Material Type and Thickness:

- Different materials have varying optimal focal lengths and requirements. For instance, engraving on thin acrylic may require a different focus lens than cutting through thick plywood. Consider the range of materials you plan to work with and choose a lens that suits the majority of your applications.

- Spot Size:

- The spot size is the diameter of the focused laser beam. A smaller spot size allows for finer details in engraving, while a larger spot size is more suitable for cutting thicker materials. Balance your requirements for precision and speed when selecting the spot size.

- Lens Coating:

- Anti-reflective coatings on lenses can enhance the efficiency of the laser system by reducing losses due to reflections. High-quality coatings can also improve the durability of the lens and minimize the need for frequent replacements.

- Power Density:

- The power density, or intensity, of the laser beam is influenced by the combination of laser power and spot size. Ensure that the chosen focus lens can handle the power density of your CO2 laser system without compromising performance or risking damage to the lens.

In conclusion, choosing the ideal focus lens for your CO2 laser system is a critical decision that directly impacts the quality and efficiency of your laser applications. Consider factors such as focal length, material type, spot size, lens coating, and power density to make an informed decision. Regular maintenance and proper cleaning of the lens are also essential to ensure consistent performance over time.

By investing time and effort in selecting the right focus lens, you can unlock the full potential of your CO2 laser system, achieving optimal results in cutting, engraving, and marking a diverse range of materials.

Credit: Image by Image by pressfoto on Freepik