In the intricate world of fiber laser cutting, precision is not just a goal but a necessity. Among the many components that contribute to this precision, the auto-focus system plays a pivotal role. In this article, we’ll delve into the fascinating influence of electromagnetic fields on auto-focus systems, specifically those found in cutting-edge tools like Raytools.

Understanding the Auto-Focus System:

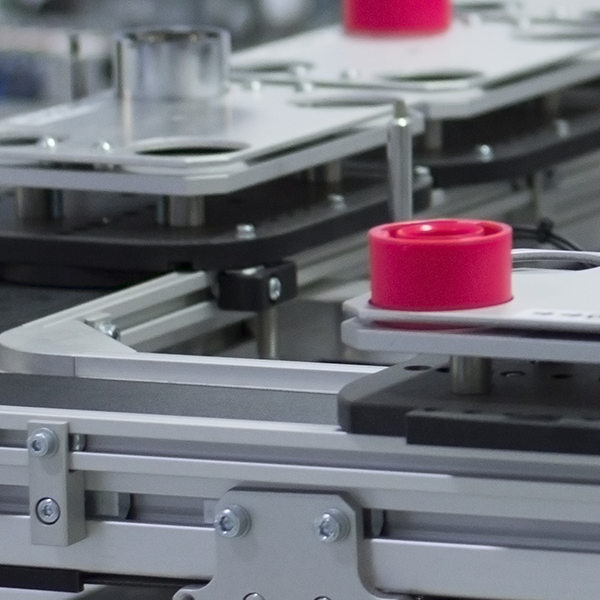

Before we explore the impact of electromagnetic fields, let’s grasp the significance of the auto-focus system in fiber laser cutting heads. This ingenious system is designed to dynamically adjust the focus of the laser beam in real-time, ensuring optimal cutting performance across various material thicknesses and shapes.

The Role of Electromagnetic Fields:

In the realm of fiber laser cutting heads, the auto-focus system’s functionality can be influenced by electromagnetic fields. Raytools, a leading name in laser technology, incorporates advanced auto-focus systems that are sensitive to their electromagnetic surroundings.

Key Considerations:

- EMI (Electromagnetic Interference): Electromagnetic interference from external sources can impact the accuracy of the auto-focus system. Understanding and mitigating EMI is crucial for maintaining consistent and precise cutting.

- Shielding Solutions: Implementing effective electromagnetic shielding solutions is paramount. Raytools’ cutting-edge designs often include features to minimize the impact of external electromagnetic fields on the auto-focus mechanism.

- Auto-Focus Calibration: Regular calibration of the auto-focus system is essential to counteract any variations induced by electromagnetic fields. This ensures that the system continues to deliver pinpoint accuracy.

Visualizing the Impact:

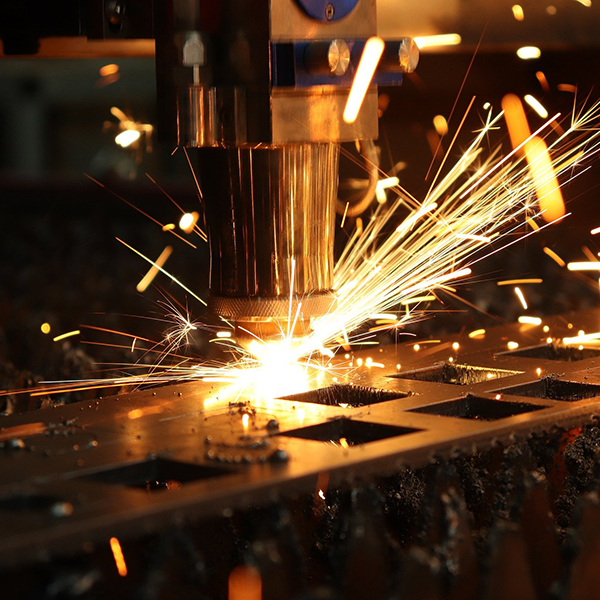

Let’s visualize the intricate dance between electromagnetic fields and auto-focus precision:

- Auto-Focus Adjustment Process: Illustration depicting how the auto-focus system dynamically adjusts to maintain optimal focus, highlighting the impact of electromagnetic fields.

- Comparison of Cutting Precision: Side-by-side comparison of cutting precision with and without effective electromagnetic shielding, showcasing the tangible impact on the end results.

Benefits of Addressing Electromagnetic Fields:

- Consistent Cutting Quality: By addressing the influence of electromagnetic fields, Raytools’ auto-focus systems ensure consistent and high-quality cutting across diverse materials.

- Extended System Lifespan: Minimizing the impact of external electromagnetic interference contributes to the longevity of the auto-focus system and the overall lifespan of the fiber laser cutting head.

Conclusion:

As we navigate the intricacies of fiber laser cutting technology, understanding the influence of electromagnetic fields on auto-focus systems becomes pivotal. Raytools, with its commitment to cutting-edge solutions, ensures that the auto-focus systems in their fiber laser cutting heads remain resilient in the face of external electromagnetic influences.

By acknowledging and addressing the impact of electromagnetic fields, we pave the way for a future where precision in laser cutting is not just a goal but a steadfast reality. Explore the realm of Raytools and experience the seamless fusion of technology and precision in every laser cut.

Credit: Image by Freepik