In the world of CO2 lasers, where precision and efficiency are paramount, the choice of components plays a pivotal role. Among these components, the diameter of the lens is often underestimated but holds immense significance in shaping the outcome of laser applications. In this article, we’ll delve into the importance of lens diameter and how it can impact the performance of your CO2 laser system.

Understanding Lens Diameter:

The diameter of a lens refers to the size of its optical surface. In the context of CO2 lasers, the lens diameter is a critical factor influencing the laser beam’s characteristics and, consequently, the cutting, engraving, or marking process.

Factors Influencing Lens Diameter:

- Power Handling Capacity:The diameter of the lens is closely linked to its power-handling capacity. Larger diameter lenses can efficiently handle higher laser power levels. This is particularly crucial for applications that demand intense laser energy, such as cutting through thick materials.

- Beam Quality:The diameter of the lens is intricately tied to the beam quality it can achieve. A larger diameter lens can contribute to a more stable and focused laser beam, resulting in improved precision in the laser application

- Material Compatibility:Different materials respond differently to laser processing. The lens diameter should be chosen based on the specific requirements of the material you are working with. For example, when engraving intricate details on delicate surfaces, a smaller diameter lens might be more suitable

Visualizing the Impact:

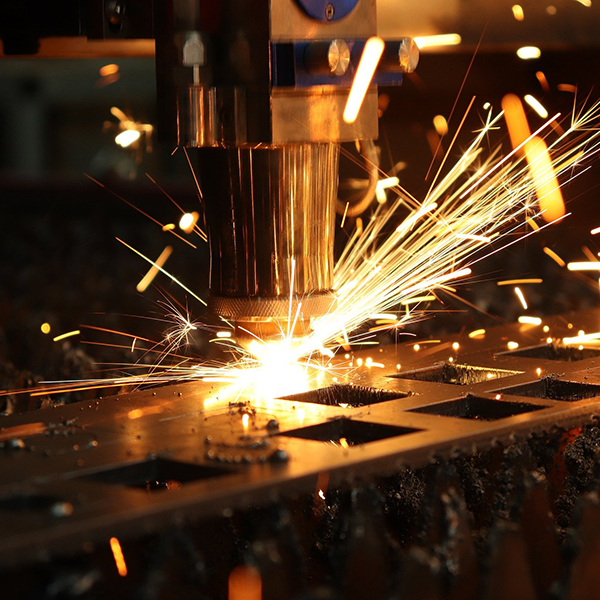

Let’s take a closer look at how lens diameter can visually impact laser applications:

- Comparison of Beam Profiles:Visual representation of how different lens diameters can affect the beam profile, showcasing the difference in focus and intensity.

- Material Cutting Depth:Illustration depicting how the lens diameter influences the cutting depth in materials of varying thickness.

Choosing the Right Lens Diameter:

Selecting the appropriate lens diameter involves a careful consideration of your specific application requirements. Here are some general guidelines:

- Smaller Diameter Lenses:

- Ideal for applications requiring fine details and precision.

- Suitable for engraving and marking on delicate surfaces.

- Medium Diameter Lenses:

- A balanced choice for versatility in various applications.

- Offers a good compromise between precision and power handling.

- Larger Diameter Lenses:

- Preferable for applications demanding higher laser power.

- Efficient for cutting through thicker materials.

Conclusion:

In the intricate world of CO2 laser systems, the lens diameter is a nuanced but crucial element that can significantly influence the outcome of your laser applications. By understanding the impact of lens diameter on power handling, beam quality, and material compatibility, you can make informed choices that enhance the precision and efficiency of your CO2 laser system.

Credit: Image by wirestock on Freepik