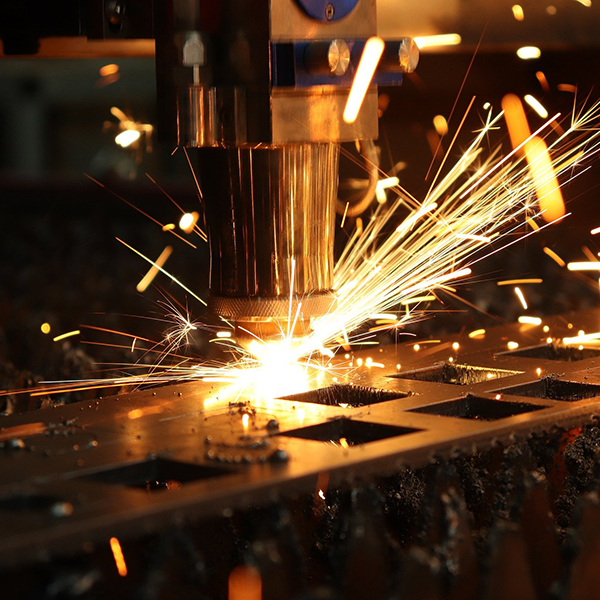

Laser ablation technology has been around for several years and is becoming increasingly popular across a wide range of industries, including medical, manufacturing, and research. This technology is used to remove or modify the surface of a material by focusing a high-intensity laser beam onto the surface. The process vaporizes the material, leaving behind a small crater or removing the surface layer completely.

Laser ablation technology has several advantages over traditional mechanical methods of material removal. It is a non-contact process, which means that there is no risk of damaging the material due to physical contact. It also provides a high level of precision, making it ideal for applications where accuracy is critical. Additionally, laser ablation can be used on a wide range of materials, including metals, plastics, ceramics, and composites.

One of the key factors that affect the performance of laser ablation is the wavelength of the laser used. Different wavelengths are absorbed by different materials in different ways. UV, green, and infrared are the most common wavelengths used in laser ablation technology. In this article, we will discuss the differences between these wavelengths and their applications in laser ablation.

UV Lasers

UV lasers have a wavelength range of 100 to 400 nanometers. They are commonly used in applications that require high-precision ablation, such as microelectronics and medical device manufacturing. The high-energy UV photons are absorbed by the material, leading to localized heating and vaporization of the surface.

UV lasers are particularly effective in removing thin films and coatings. They are also used in photolithography, a process used in the manufacturing of microelectronics. In photolithography, a UV laser is used to selectively remove the protective layer on a silicon wafer, exposing the underlying layer to be etched.

Green Lasers

Green lasers have a wavelength range of 500 to 550 nanometers. They are commonly used in applications that require high-precision ablation on a larger scale, such as industrial manufacturing and aerospace. Green lasers are absorbed less by materials than UV lasers, but they have a higher energy density, making them more effective at ablating thicker layers.

Green lasers are also used in laser engraving and marking applications. They can create highly detailed and precise marks on a wide range of materials, including metal, plastic, and glass.

Infrared Lasers

Infrared lasers have a wavelength range of 800 to 1,000 nanometers. They are commonly used in applications that require high-power ablation, such as cutting and welding. Infrared lasers are absorbed by materials more efficiently than UV or green lasers, making them effective at ablating thicker materials.

Infrared lasers are commonly used in the automotive and aerospace industries for cutting and welding metals. They are also used in medical applications, such as removing tumors or treating skin conditions.

In summary, the wavelength of the laser used in laser ablation technology plays a critical role in its effectiveness. UV lasers are best suited for high-precision ablation, while green lasers are ideal for larger scale precision work. Infrared lasers are used for high-power ablation, such as cutting and welding. The choice of wavelength depends on the specific application and the material being ablated.

Laser ablation technology has many advantages over traditional methods of material removal, including high precision, non-contact, and a wide range of applicable materials. However, it is important to choose the right wavelength of laser for the specific application to ensure optimal performance and results.