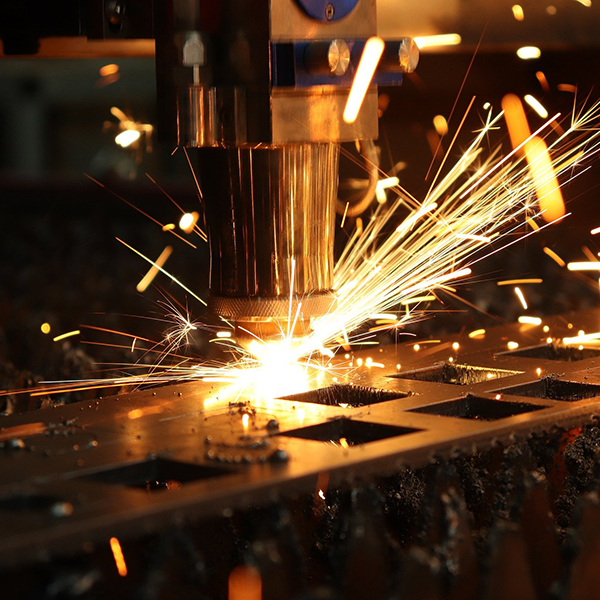

In the realm of laser marking, precision is paramount. Fiber marking laser machines have revolutionized the world of engraving and marking with their speed and accuracy. At the heart of this precision lies the quality of the laser beam. In this article, we’ll explore the crucial role that laser beam quality plays in determining the success of your fiber marking endeavors.

Understanding Laser Beam Quality:

Laser beam quality refers to the spatial and temporal characteristics of the laser beam. In simpler terms, it’s about how well the laser maintains its focus and intensity over a given distance and time. For fiber marking laser machines, high beam quality is synonymous with sharper, more accurate markings.

Factors Influencing Laser Beam Quality:

- M2 Factor: The M2 factor is a measure of how closely the laser beam profile resembles that of an ideal Gaussian beam. A low M2 value indicates a beam that is close to ideal, translating to better focus and precision in marking.

- Divergence: Divergence measures how quickly the laser beam expands as it travels away from the source. A low divergence is crucial for maintaining a focused beam over longer distances, ensuring consistent and accurate marks.

- Beam Profile: The shape of the laser beam profile matters. An even, well-defined beam profile contributes to uniform marking and prevents inconsistencies in the engraved surface.

Visualizing the Impact:

Let’s visualize the impact of laser beam quality on marking precision:

- Comparison of Marking Quality: Side-by-side comparison of markings achieved with different laser beam qualities, highlighting the superior precision of high-quality beams.

- Effects on Small Text and Details: Illustration demonstrating how high beam quality enables the crisp engraving of small text and intricate details, showcasing the importance in industries such as electronics and jewelry.

Benefits of High Laser Beam Quality:

- Fine Detailing: Achieve intricate details and fine lines in your markings, making fiber laser marking suitable for applications requiring high precision.

- Consistent Depth and Contrast: High beam quality ensures consistent marking depth and contrast across various materials, providing uniform results.

- Extended Focal Range: Enjoy a broader focal range, allowing for flexibility in marking on uneven surfaces or varying material heights.

Choosing the Right Fiber Laser:

When investing in a fiber marking laser machine, consider the following:

- Check the M2 Value:

- A low M2 value, ideally close to 1, indicates high beam quality.

- Evaluate Divergence:

- Lower divergence values contribute to better focus and marking precision.

- Review Beam Profile:

- Look for a laser with a well-defined and even beam profile.

In the intricate world of laser marking, the quality of the laser beam is the linchpin to success. The precision and sharpness achievable with high beam quality in fiber marking laser machines open doors to a myriad of applications, from industrial part marking to artistic engraving.

Investing in a laser system with superior beam quality is an investment in the accuracy and efficiency of your marking processes. As you explore the world of fiber laser marking, let the beam quality be your guiding light towards unmatched precision and excellence.

Credit: Image by Freepik